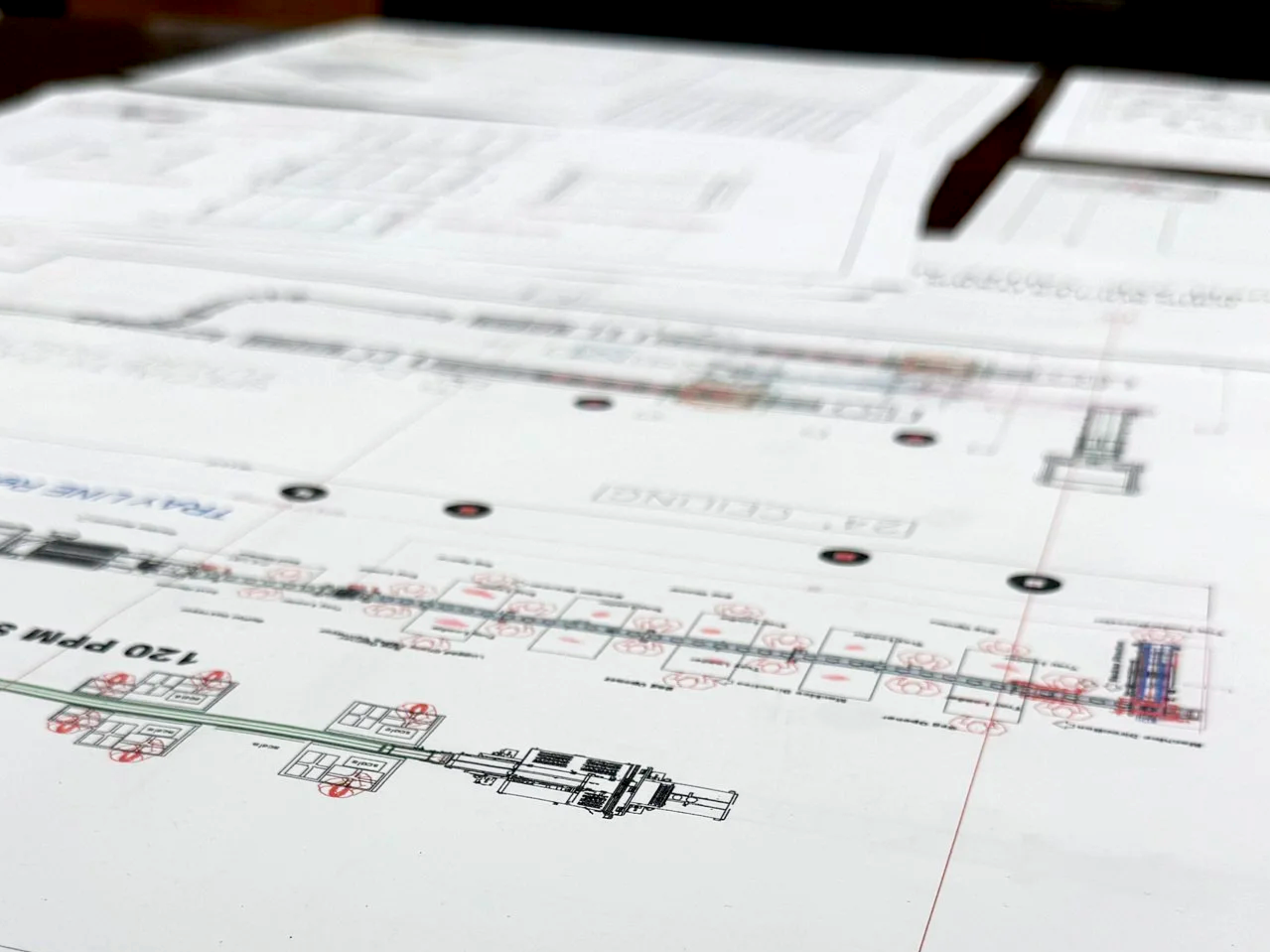

Field-Verified Design: We don’t design in a vacuum. Theoretical perfection fails if it ignores a support column, a sloping floor, or a forklift’s turning radius. Our process begins on your plant floor, not in our office. We map your specific spatial constraints, identify workflow bottlenecks, and account for operator interaction. We engineer equipment that fits your existing infrastructure and workforce seamlessly, eliminating costly installation surprises.

Precision Millwright Services: Our installation teams specialize in executing complex projects within active facilities ("brownfield" environments). We are experts at integrating new systems into tight footprints without disrupting adjacent operations. Whether navigating rigid schedules or threading equipment through existing production lines, we bridge the gap between technical drawings and operational reality. We ensure the solution is not just installed to spec, but calibrated to work.

Rapid Response & Operational Support: Breakdowns rarely happen during convenient hours. We understand that unplanned downtime equates to lost revenue. FSG operates as a strategic partner for critical maintenance and emergency fabrication. When production stops, we mobilize with the materials, tooling, and manpower required to restore operations immediately. We design, build, install, and repair with a single goal: keeping your business moving.